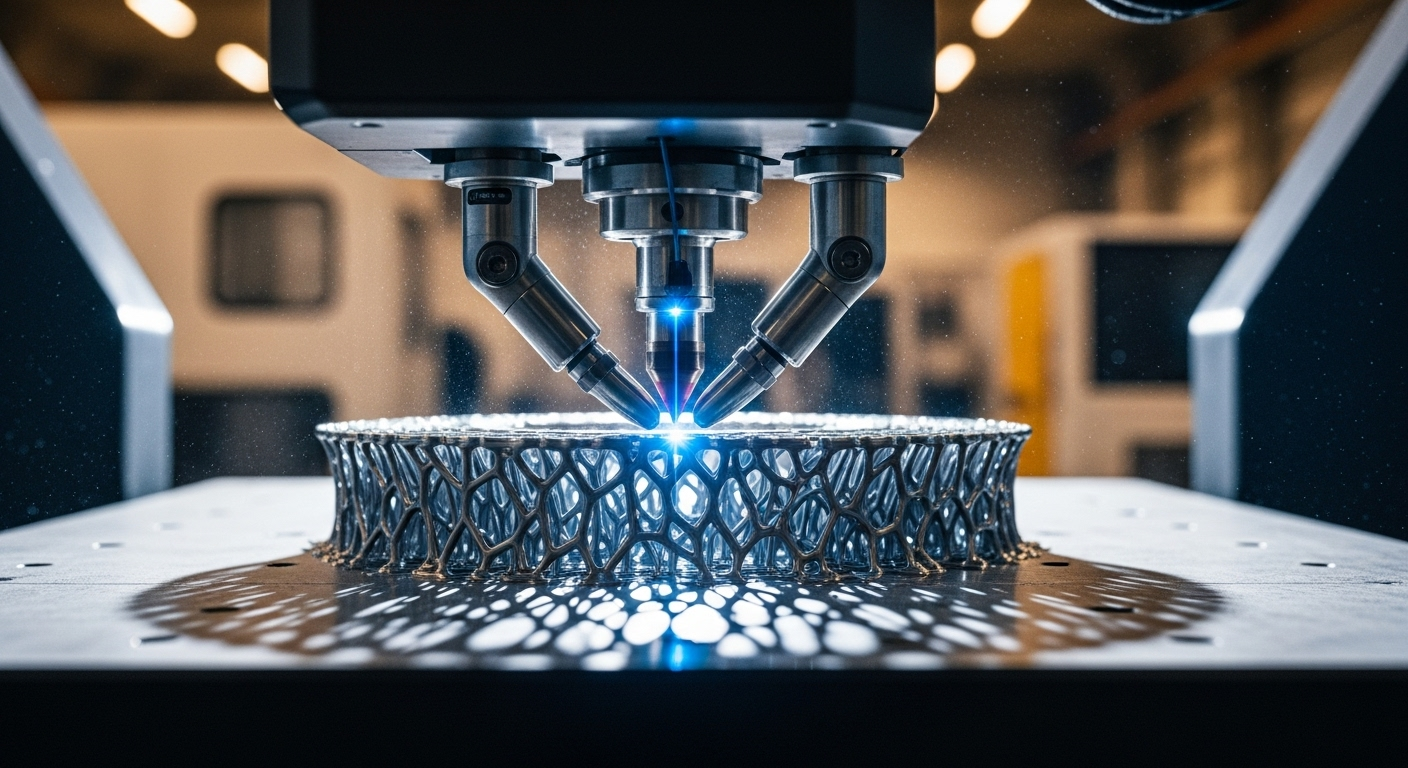

Laser Welding: Advanced Technology for Precision Metal Joining

Laser welding represents a significant advancement in metal joining technology, offering unprecedented precision and quality for manufacturing industries. This sophisticated process harnesses concentrated light energy to create strong, clean connections between metal components. Unlike conventional welding methods that rely on physical contact and substantial heat input, laser welding operates with minimal thermal impact while delivering exceptional results. As industries continue to demand higher precision, greater efficiency, and improved quality in metal joining, laser welding technology has emerged as a preferred solution across automotive, aerospace, medical device manufacturing, and other precision-oriented sectors.

How Does Laser Welding Work in Precision Applications?

Laser welding utilizes a high-energy beam of concentrated light to create a precise fusion between metal components. The process begins with a laser generator that produces an intense, highly focused beam. When this beam strikes the metal surface, the concentrated energy rapidly converts to heat, causing the metal to melt at the joint interface. The molten metals flow together and solidify to form a strong weld. What makes laser welding exceptional for precision applications is the incredibly small heat-affected zone (HAZ) and the ability to control beam parameters with exceptional accuracy. The narrow beam can focus on areas as small as 0.01mm in diameter, allowing for welds in extremely tight spaces or on miniature components where traditional welding would be impossible.

What Are the Key Differences Between Laser and Traditional Welding?

Traditional welding methods like MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and arc welding rely on much broader heat application and often require filler materials. These processes typically create larger heat-affected zones that can lead to material distortion, especially in thin or heat-sensitive materials. Laser welding, by contrast, delivers energy in a highly concentrated manner, minimizing heat input while achieving deep penetration. While traditional welding often requires access to both sides of a joint, laser welding can achieve full penetration from just one side. Another significant difference is speed—laser welding can operate at velocities up to 10 meters per minute in some applications, dramatically outpacing conventional methods. Additionally, traditional welding generally requires more extensive post-weld cleaning and finishing, whereas laser welds often need minimal secondary processing.

What Materials Can Be Joined Using Laser Welding Technology?

Laser welding demonstrates remarkable versatility in joining a wide range of materials. It excels with most metals including stainless steel, carbon steel, aluminum, titanium, and various alloys. The technology particularly shines when working with dissimilar metals that would be challenging or impossible to join with conventional methods. For instance, laser welding can create successful joints between copper and aluminum, stainless steel and titanium, or even some metal-to-ceramic combinations with specialized techniques. The process is also ideal for thin materials (down to 0.01mm thickness) where traditional welding would cause warping or burn-through. However, materials with high reflectivity like copper and aluminum can be more challenging to weld with certain laser types, though advancements in beam technology have largely overcome these limitations.

What Are the Primary Benefits of Laser Welding for Manufacturing?

Laser welding offers several significant advantages that have made it increasingly popular in precision manufacturing. First, the minimal heat distortion preserves the dimensional accuracy of components, crucial for parts with tight tolerances. The clean, narrow welds create aesthetically appealing seams that often require no additional finishing, saving time and cost in post-processing. Laser welding also enables deep, narrow penetration welds without filler material, resulting in stronger joints with less added mass. The non-contact nature of the process eliminates electrode wear and contamination issues common with traditional methods. Additionally, laser welding can be fully automated and integrated into production lines, offering exceptional repeatability and reliability. Many manufacturers report significant improvements in throughput and reduction in rejection rates after implementing laser welding technology.

How Is Laser Welding Equipment Configured and Operated?

Laser welding systems consist of several key components working in harmony. The core element is the laser source—typically fiber, Nd:YAG, or CO2 lasers—which generates the high-energy beam. This beam travels through a delivery system of mirrors or fiber optics to reach the workpiece. Most industrial setups include sophisticated motion systems that precisely position either the beam or the workpiece according to programmed patterns. Modern laser welding stations incorporate advanced vision systems and real-time monitoring to ensure weld quality and consistency. The equipment requires skilled operators who understand not only the welding process but also the physics of laser-material interaction. Programming these systems involves setting critical parameters like power density, pulse characteristics, travel speed, and focus position—all of which significantly impact weld quality. Most systems offer both manual operation for prototype development and fully automated modes for production runs.

What Are the Cost Considerations and ROI for Laser Welding Systems?

Investing in laser welding technology requires careful financial analysis as initial equipment costs typically exceed those of conventional welding systems. Entry-level industrial laser welding systems start around $80,000, while comprehensive production cells with automation and quality monitoring can exceed $500,000. However, the return on investment often justifies the initial expenditure through multiple channels. Operational costs can be lower due to reduced energy consumption, minimal consumables, and decreased need for post-processing. Many manufacturers report labor savings of 30-50% compared to traditional welding methods for precision applications.

| Laser Welding System Type | Approximate Cost Range | Key Applications | ROI Timeline |

|---|---|---|---|

| Entry-Level Manual System | $80,000 - $150,000 | Small-batch production, R&D | 2-3 years |

| Mid-Range Semi-Automated | $150,000 - $300,000 | Medium production, precision components | 1-2 years |

| High-End Fully Automated | $300,000 - $750,000+ | High-volume production, critical applications | 1-1.5 years |

| Custom Integrated Cell | $500,000 - $1,500,000+ | Specialized manufacturing, automotive, aerospace | 1-2 years |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Laser welding represents a significant technological advancement in metal joining, offering unprecedented precision, speed, and quality compared to traditional methods. While the initial investment may be substantial, the combination of improved product quality, reduced post-processing requirements, and increased production efficiency typically delivers compelling long-term value. As manufacturing continues to evolve toward greater precision and automation, laser welding technology will likely become even more prevalent across industries requiring high-quality, repeatable joining of metal components.